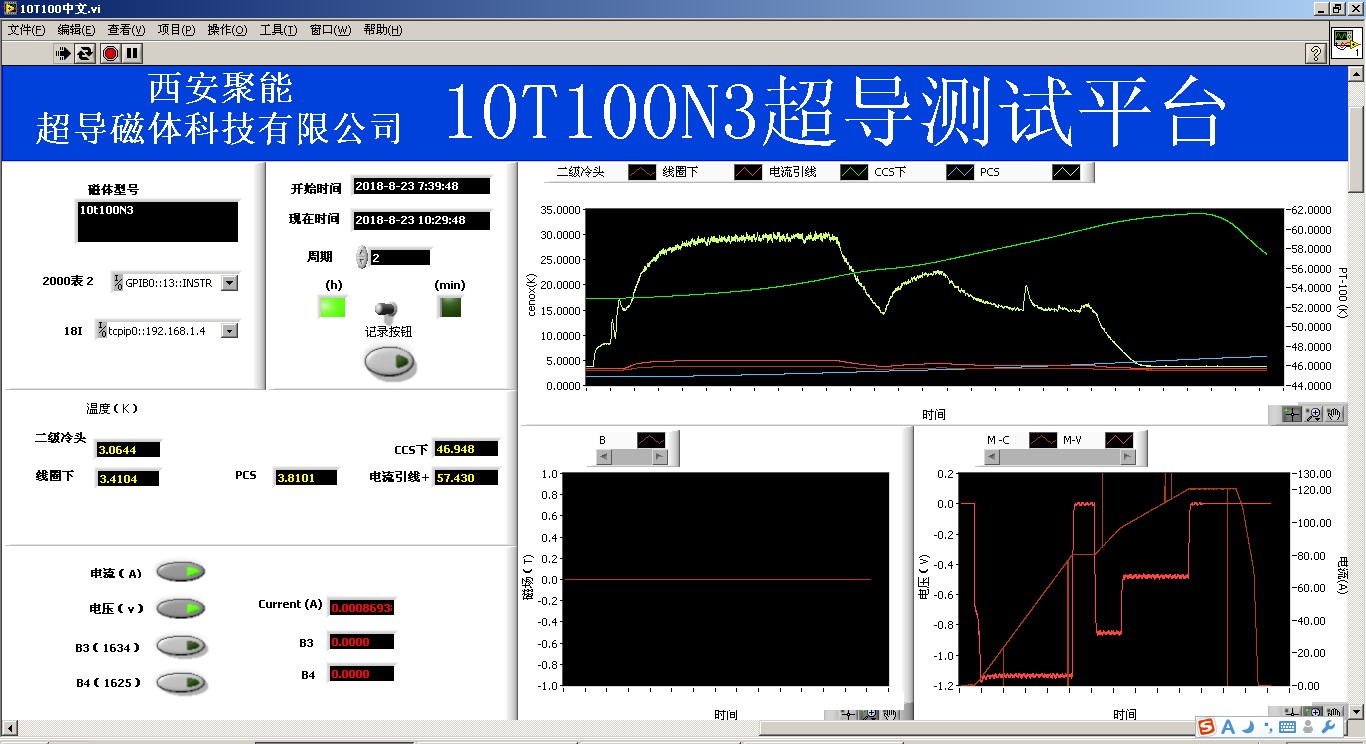

Recently, Xi 'an Juneng Superconducting Magnet Technology Co., LTD., a subsidiary of Western Superconductor, independently developed a 10T100mm refrigerator with closed-loop operation function to directly cooling the non-liquid helium superconducting magnet successfully completed the test. All the technical indicators were better than the design value, and the lowest temperature of the magnet reached 3.4k, filling the gap in China. After 2T84, 3.6T160, 6T84, 8T100, 10T100, 13T40 and other open-loop operated direct-cooled magnets, this is the first time to realize zero-resistance closed-loop operation of NbTi and Nb3Sn hybrid superconducting magnets, marking another major leap in the design and manufacture of high field superconducting magnets without liquid helium.

Since superconducting magnet needs superconducting power supply to work, once the power supply problem occurs, the magnetic field of magnet will disappear immediately and variable field operation will occur. However, if power supply disconnection can be realized in the application of stable magnetic field, that is, closed-loop operation mode, it can not only reduce the operation cost of the magnet, but also avoid the failure or damage of the magnet caused by the problem of the magnet power supply. But because the key technology of constant-current mode switch which is applied to refrigerating machines in China has not been broken yet, the switch with special low-temperature superconducting wires relies on import for a long time, and the magnet manufacturing technique is limited for this mode. In our country, high field magnets without liquid helium for scientific research and industry have not been able to realize closed loop operation for a long time, which severely restricts the popularity of superconducting magnets. And seriously hinder the above key areas of industrial development and technological progress.

After six months of joint research, the superconducting wire workshop of Western Superconductor Company and Poly Magnet Company broke through a number of core and key technologies for the first time in China, such as "preparation of superconducting wire for PCS", "design and manufacture of refrigerating machine directly cooling PCS", "refrigerating machine directly cooling magnet closed-loop" technology, eliminating the equipment's dependence on liquid helium resources and power supply. It can save a lot of operating costs for users of scientific research and industrial manufacturing. In the future, the company will take this opportunity to continue to accelerate the expansion of high-performance superconducting magnets application field, to meet the urgent needs of domestic and foreign customers.

热门新闻

- Xi 'an polymer superconducting magnet Liu Wei has been selected into the "Xi 'an Talent Plan" young talent project

- 【 Good News 】 The Western Superconducting Subsidiary's Concentrated Magnet has been approved to build the Shaanxi Province Superconducting Strong Magnetic Field Engineering Research Center

- Everyone talks about safety, everyone knows emergency measures, and all departments of concentrated magnets carry out a series of safety education activities through "multi pronged approach"

- Xi 'an shaped superconducting magnet won the first prize of 2021 Shaanxi Provincial Patent Award

- Western Superconductor Company to the poor area of Zhashui County to provide charity donations

关注我们

微信搜索“超导磁体”或扫码关注公众号随时了解更多超导磁体资讯

微信搜索“超导磁体”或扫码关注公众号随时了解更多超导磁体资讯

陕公网安备61019102000511号

陕公网安备61019102000511号